Metal Composita Exterior Panels Production Line

Description:

Metallum compositum exsculptum in tabulis exterioribus productio Linea est productio novi generis environmentally- amicae leve pondus materiae aedificationis quae nunc in mundo vulgaris sunt.et decorat tabulas murus in polyurethane spuma.Retardans scelerisque velit tabulata cum lamina ferrea in superficie ex aere decorat ignium potest producere.polyurethane in medio.aluminium claua vel lamina in imo ferro.

Product Detail

Product Tags

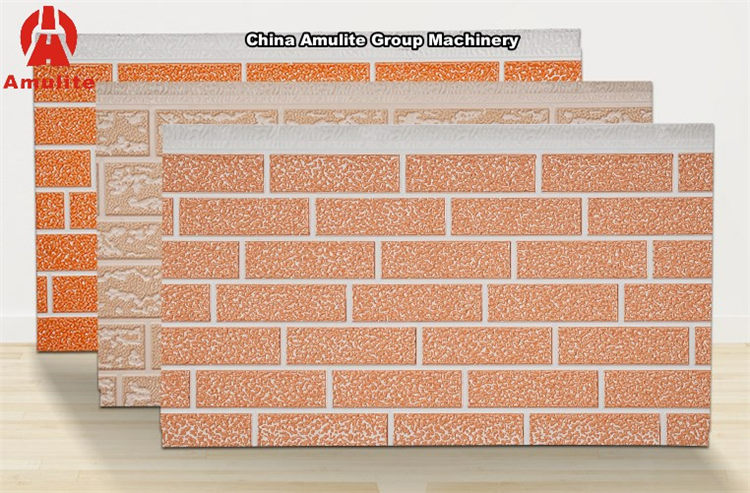

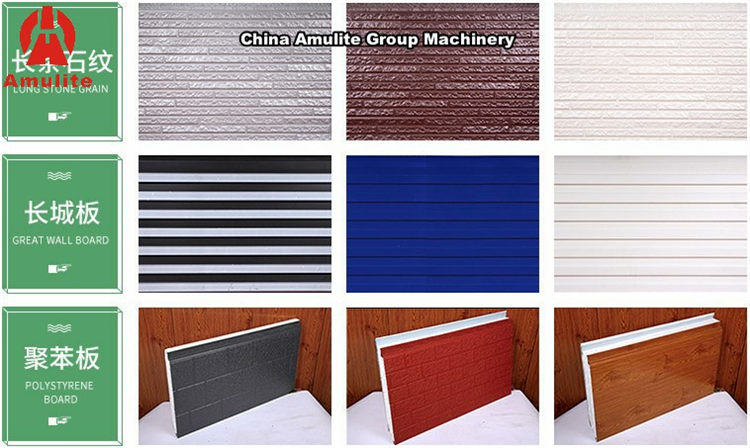

1. Wall Panel Introduction

Metallum compositum exsculptum in tabulis exterioribus productio Linea est productio novi generis environmentally- amicae leve pondus materiae aedificationis quae nunc in mundo vulgaris sunt.et decorat tabulas murus in polyurethane spuma.Retardans scelerisque velit tabulata cum lamina ferrea in superficie ex aere decorat ignium potest producere.polyurethane in medio.aluminium ffoyle vel lamina in fundo. Praecipua applicatio regionum productorum: renovatio aedificiorum veterum.summus terminus villae conclavium.villae.hotels.levi ferro structurae.mobilibus domibus.villarum.magna shopping malls.moenibus interioribus et exterioribus officinis.etc.

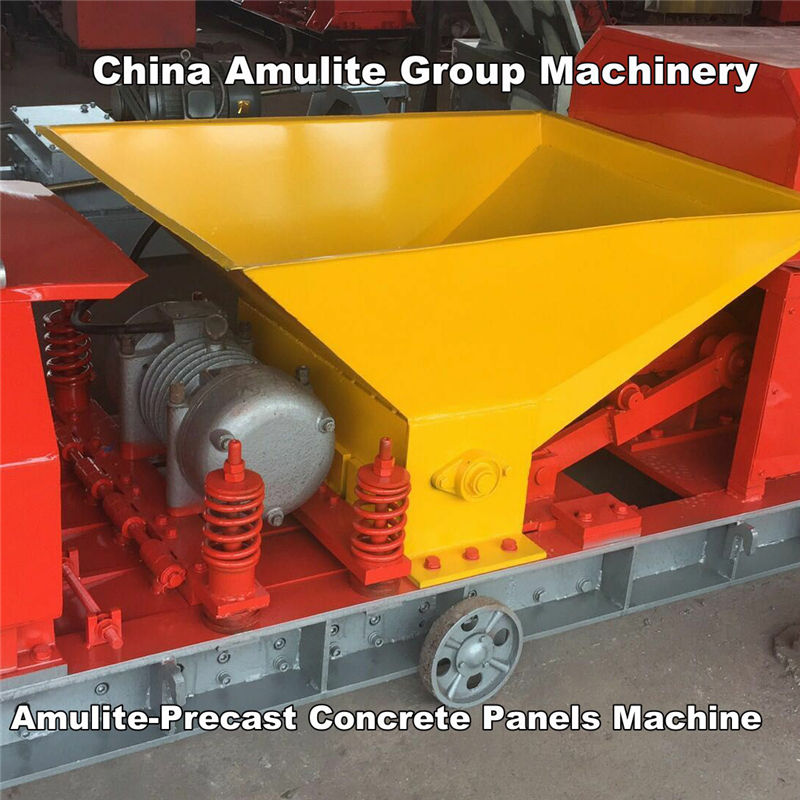

2. Compositio Equipment

Caelum Metal Compositum Exterior Tabulata Productio Linea Main Unwinder → Embossing Machina → Adaequatio Machina → Latus Formans Machina → Calefaciens Rostra → Ab Spuma Machina Iniectio → Aluminium Catena Tabule Laminating Machina → Viderit Tabula Abscindere → Donec → Stipare Etc.

Metal Composita Exterior Panels Production Line Main Technical Parameters

Wall Panel Specification:A.380×16mm B. 380-500)×(30-40)mm

Productio Speed:4-10m/min

Aluminium Alloy Duplex Crawler:18-24m

Totalis virtutis Equipment:De 60Kw

Productio Linea Capacitas:circa 1. 000. 000Sq.m.

Metal Composita Exterior Panels Production Line Introduction Of Unit Structure Et Function

Ⅰ.Unwinder

Munus, propter Unwinding et scalpendi Ferro gyros

Structure Type:Section Steel Welding Frame.The Lateral Displacement is realized by Hydraulic Cylinder.Ne deviatio Coil Material.Unwinding adoptat passivum Type.Have Pneumatica Brake Tensionem Control.

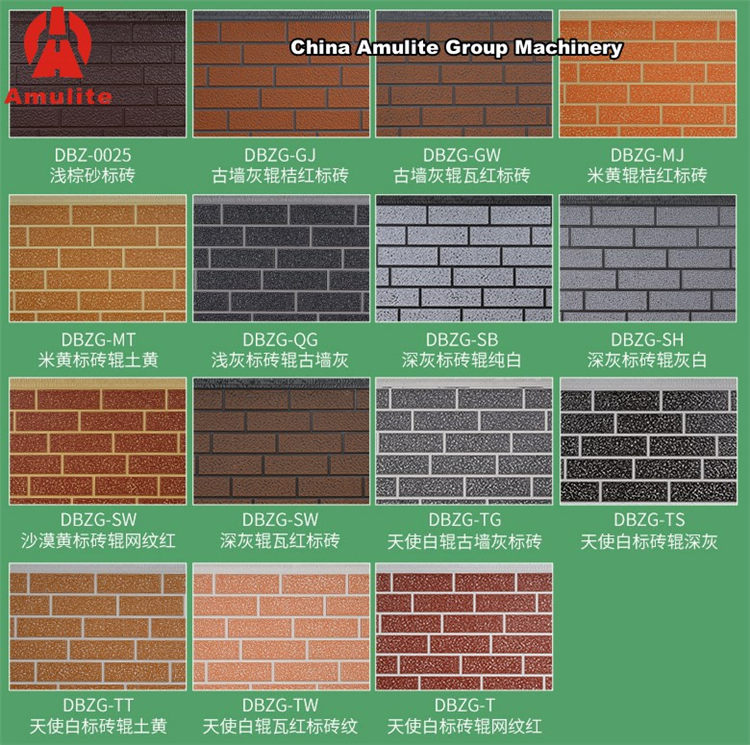

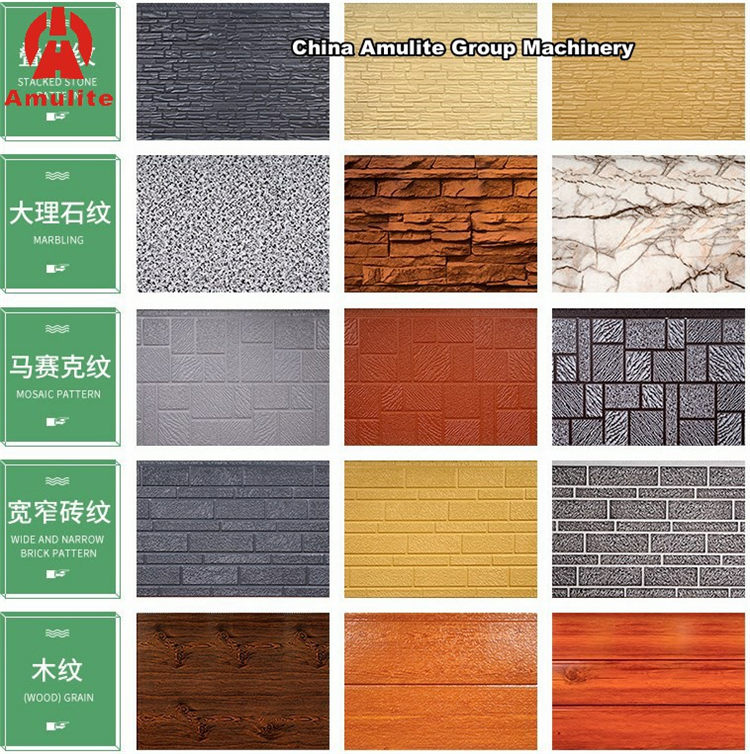

Ⅱ.Embosting Machina

Function:Secundum diversa exemplaria Wall Panel.Duae oppositae Embossing Metallis Rolleri diversis Patterns Coloris Steel instare sunt.

Ⅲ.Spumans Machina

BLC(R) Type Low Pressure Continuous Spumans Machina Or PH(R/F) High Pressure Spumeing Machine.Utere 1 Resina (A) Lacus.1个 Curing Agent (B) Tank;The Two Metering Pump Unitates expelluntur Independentes Variabiles Frequency Motors.In output fluxum Metering Pump regitur mutando velocitatem Metering Pump。Finally.Components mixta sunt secundum rationem debitam et aequaliter sparsi inter laminas inferiores Ferri aut aliae Substratae.

Ⅳ.Formare Machina

Function: Figura caelati Coloris Steel tractata est per Multi Rota Flanging.

Ⅴ.Laminator

Function:Complete Online Spumatio et formatio Polyurethane; Catenae Plate Unit componitur De Coegi Motor.Catena Rota.Aluminium Alloy Chain Plate.Pin Shaft And Rolling Bearing.Usura Electric Calefaciens Tube Calefaciens Methodo; Cito Calefacere Potest Duplex Cingulum Machina Ad Requiritur Temperatura Pro productione。 Cum Temperature attingit Preset Value.Electric Calefactio verti potest in vel off secundum actualem Situ.

Ⅵ.Certa Longitudo Sawing Machina

Munus vidit formatae Board Secundum ad set Size.

Function:The Base.Fuselage et superius mobile frame Adopt Sectio Ferro et Plate Welding Structure.Connected By Linear Guide Rail.Adscendens Superficies Guide Rail consummatum est.Curare instruitur AccuracyThe Sawing Motor installatur in superiori Moving Frame.Movens Frame agitatur Apparatus motor.Motus lateralis - Clamping Fabrica in corpus installatur.Componitur ex aere cylindro et premente Block; Reset fabrica componitur cylindri et quiddam fabrica; Cum lamella attingit Set Longitudo.Clamping Cylinder impellit clamping Block Down.Et Reset Cylinder corpus impellit ad movendum cum Plate;EODEM TEMPORE.Secandum motor est Coepi.Motrix Reductio Motrix Artus Movens Horizontaliter Superum Agitet.So As to know the Transverse Secans Of The Plate;Post sectionem efficitur.Clamping Fabrica elevatur.Et Reddere cylindrum agit corpus redire ad pristinum punctum Reset.

5. Embossed Metal Compositum Exterior Panels Production Line Automatic Control

Systema Automatica Imperium in quattuor Partes divisum est: Unwinding and Embossing Area Control.Formans et Lamination Area Control.Spumans Area Imperium Et Sawing Area Control.Summa potestas est circa 60KW;The Calefactio rostra est de 30KW.Tota Control System consistit Programmabili Controller.Test Cie.Delta Inverter Coegi And Other Components.Per Tactus Screen Parameter Input And Button Cooperation Operation.Animadverto Automated productione productio Line.Eius euismod firmus et stabilis est.Et operatio simplex et facilis est.